Cormatex manufactures complete lines for the production of thermobonded and needle punched nonwovens designed for the production of hi-density and hi-loft (low-density) products with different composition as well as physical and mechanical features, with the ability to process natural or manmade, virgin or regenerated fibres. The high technological level being achieved due to a constant commitment of the company in R&D allows our lines producing more with a better quality.

These products are widely employed in the following application fields:

– Automotive: wadding for seats, thermal and sound insulation products, preformed panels, carpets and outer coatings for preformed panels

– Soundproofing: panels for soundproofing

– Thermal Insulation: panels for thermal insulation

– Furnishing: upholstering for sofas, armchairs, chairs, mattresses, quilts and sleeping bags, carpeting, mattresses, cleaning clothes

– Clothing: filling for winter jackets or interlining supports for clothing and furnishing

– Medical: surgery cloths, operating table cloths, surgical masks

– Hygiene/Bodycare: baby and lady diapers, disposables, sanitary napkins, coverstocks

– Building: geotextiles (roads, dams, supports/substrates for coating)

– Shoes: manmade leather or substrates for impregnation and coating

– Filtration: dry filters (air) and wet-system filters (liquids)

– Agriculture: greenhouses and fertilising systems for desert areas

– Environment: draining systems for marshlands

– Civil defence: supports for river banks or river barrages

– Aerospace industry: components for airplane construction

– Protective clothing: bullet-proof jackets, fireproof protections for firemen

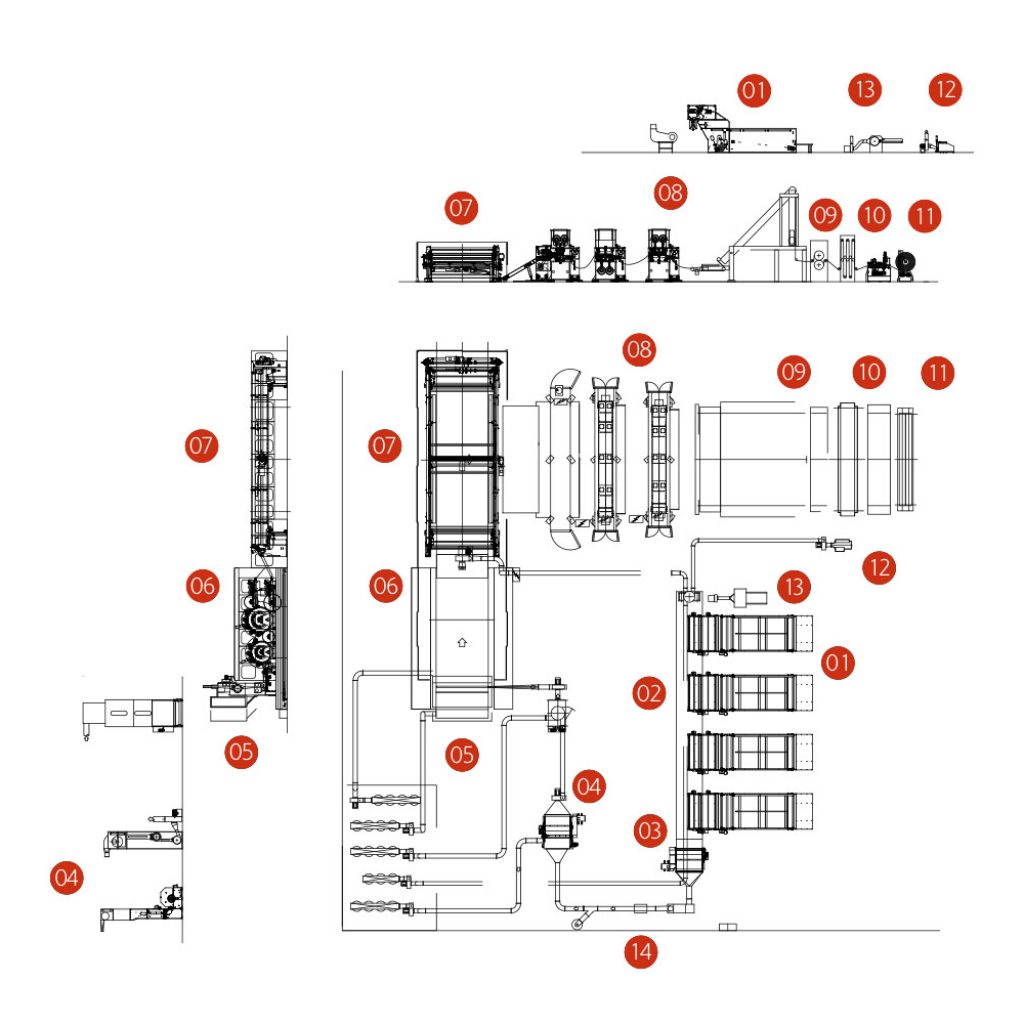

Process flow

Thermobonding

01. Bale opener

02. Transversal collecting belt

03. Beater mixer04. Oil emulsion system

05. Fine opener 06. Volumetric feeder

07. Double doffer card

08. Cross lapper mod. FR150 profile

09. Needle-punching machine

10. Thermobonding oven

11. Cutting and wind-up unit

12. Opener for edge trim recycling

13. Magnetic bar

14. Pipeline metal detector

Needle punching

01. Bale opener

02. Transversal collecting belt

03. Primary opener and oil emulsion system

04. Fine opener

05. Feed tower

06. Double doffer card

07. Cross lapper

08. Needle punching section

09. Hot calender

10. Longitudinal and transversal cutting machine

11. Automatic winder

12. Opener for edge trim recycling

13. Opener for defective material recycling

14. Metal detector

Applications

Clothing

Furniture

Packaging

Automotive

Building

Hygiene

Foot wear

Filters